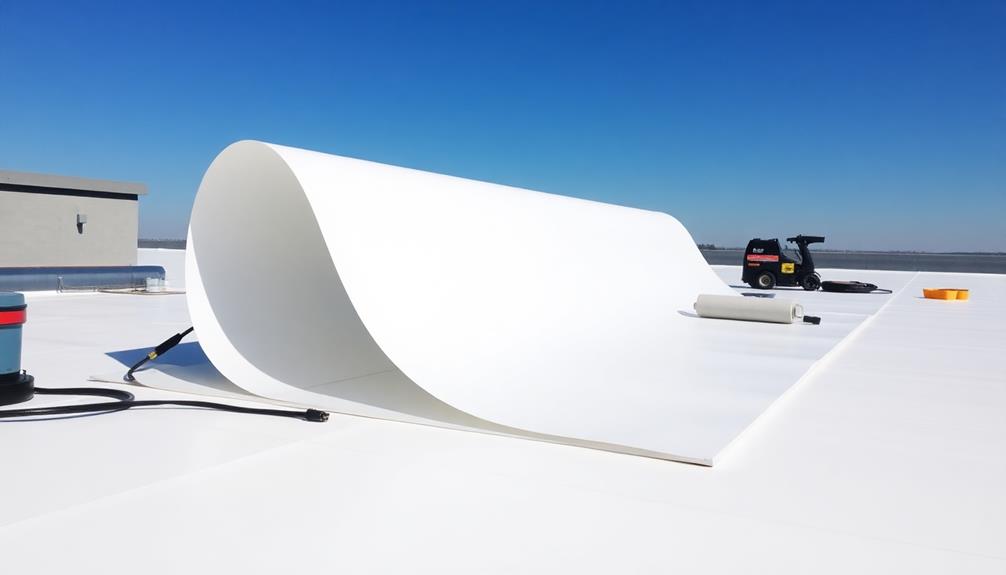

TPO Roofing Systems are advanced single-ply membranes composed of polypropylene and ethylene-propylene rubber, reinforced for enhanced strength. These systems feature a light-colored finish, boosting solar reflectance and, consequently, energy efficiency by reducing rooftop heat absorption. In regions like Colorado, TPO offers remarkable resilience against varied climates, from intense sun to heavy snow. A typical TPO roof lasts 15 to 30 years, contingent on professional installation and upkeep. Installation involves thorough surface preparation and selection of membrane attachment methods such as adhesives or mechanical fasteners. Seam sealing, using advanced heat welding, guarantees enduring waterproof integrity. Explore further to understand their full potential.

Roofing Highlights

- TPO roofing offers enhanced energy efficiency due to its reflective surface, reducing energy costs and regulating building temperature.

- It provides durability with a lifespan of 15 to 30 years, resisting chemical, UV, and environmental damages.

- TPO roofing is reinforced with polyester to offer stability, available in thicknesses from 45 to 80 mils.

- Installation options include adhered, ballasted, or mechanically fastened systems, each with specific benefits for various roof designs.

- Seam sealing techniques, like hot air welding, ensure watertight protection and are critical for roofing integrity and performance.

Definition of TPO Roofing

At ARCM Roofing, we specialize in providing top-quality TPO (Thermoplastic Olefin) roofing systems, designed to offer our customers energy-efficient, durable, and cost-effective solutions for their commercial roofing needs.

Our highly skilled team of certified professionals guarantees meticulous installation, maintenance, and repair services that meet industry standards and customer expectations. Leveraging cutting-edge technology and premium materials, we help businesses extend the lifespan of their roofs while reducing energy costs through superior thermal performance.

With a strong commitment to customer satisfaction, we offer personalized consultations and tailored solutions that address the unique needs of each project. Trust us to protect your investment with reliable, innovative TPO roofing systems that enhance building performance and sustainability.

Composition and Materials Used

Thermoplastic Olefin (TPO) roofing systems, a popular choice in commercial construction, are composed of a single-ply membrane that combines durability with energy efficiency. The TPO membrane is engineered using a unique blend of polymers, primarily polypropylene and ethylene-propylene rubber, which grants the material its robust characteristics. These components are fused together to create a highly durable layer that is resistant to tearing, punctures, and impact, ensuring longevity and resilience in various weather conditions.

The membrane is often reinforced with polyester fabric, which adds an extra dimension of stability and strength, essential for spanning across diverse architectural designs and accommodating structural movements over time. Additionally, the surface layer of the TPO membrane is often treated with ultraviolet (UV) inhibitors to safeguard against sun exposure, an integral feature given the roof’s constant exposure to harsh environmental elements.

The versatility in thickness options – generally ranging from 45 to 80 mils – allows customization based on specific project needs, providing a balance between cost-effectiveness and performance requirements. Moreover, the white or light-colored finish chosen for many TPO systems enhances solar reflectance, contributing indirectly to temperature regulation within the structure, though such benefits are explored further in subsequent discussions.

Energy Efficiency Benefits

Often touted for its impressive energy efficiency, TPO roofing systems provide several benefits that make them a preferred choice for environmentally-conscious projects. Thermoplastic olefin (TPO) membranes, known for their highly reflective surfaces, play a pivotal role in reducing energy consumption by reflecting sunlight and minimizing rooftop heat absorption.

This feature proves particularly advantageous in urban environments, where mitigating the heat island effect can lead to significant energy savings. By diminishing the need for air conditioning during peak summer months, TPO roofing not only lowers utility costs but also reduces greenhouse gas emissions, thereby contributing to sustainability goals.

In addition, TPO roofing systems can be integrated with advanced insulation materials to form an inclusive energy-efficient barrier, enhancing a building’s thermal performance. This dual benefit underscores the system’s role in lowering energy demands while providing opportunities for project designers to adhere to stringent building codes and sustainability certifications.

The membranes’ inherent UV resistance further maintains that their reflective properties do not degrade over time, preserving consistent energy performance throughout the roof’s lifespan. As a result, opting for TPO roofing represents a commitment to long-term ecological responsibility and economic efficiency, aligning with the collective pursuit of a sustainable future.

Durability and Lifespan

Reliability is a cornerstone of TPO roofing systems, setting them apart as a durable choice for modern construction. Thermoplastic Polyolefin (TPO) roofing offers a remarkable combination of resilience and longevity. Engineered to withstand the challenges posed by varying environmental conditions, TPO roofs are crafted from high-quality materials that guarantee resistance to chemicals, corrosion, and UV radiation. This robustness not only protects the building but also extends the roof’s overall lifespan, making it a prudent investment for businesses and homeowners seeking long-term solutions.

The lifespan of a TPO roof is typically between 15 to 30 years, contingent on factors such as proper installation, maintenance, and climatic influences. TPO’s inherent flexibility reduces risks of fractures under thermal expansion and contraction. Additionally, its reflective surface mitigates heat absorption, further enhancing the roof’s longevity by preventing excessive thermal stress. When adequately maintained, TPO systems demonstrate dependable performance and unwavering protection, fostering a sense of security and belonging among stakeholders who prioritize well-engineered, sustainable solutions.

Engaging with industry professionals for installation and routine inspections guarantees that a TPO roofing system performs at its optimum capacity, safeguarding the integrity of the structure beneath while promoting longevity and cost-effectiveness.

Benefits

TPO roofing systems offer numerous advantages, including an outstanding energy efficiency advantage, which helps in reducing utility costs by reflecting sunlight and decreasing heat buildup. Additionally, these systems are increasingly popular in areas like Littleton, Colorado, where residential and commercial building owners prioritize sustainable options.

Their cost-effective durability guarantees long-term performance with low maintenance needs, making them a wise investment for building owners. Furthermore, the environmental impact reduction inherent in TPO materials supports sustainable building practices by minimizing waste and utilizing recyclable components.

Energy Efficiency Advantage

In the domain of modern construction, energy efficiency has become a pivotal factor, and roofing systems play an essential role in achieving this goal. Thermoplastic Polyolefin (TPO) roofing systems are at the forefront of such advancements, offering significant energy efficiency benefits that align with both environmental sustainability and economic practicality.

This single-ply membrane roofing is specifically engineered to reflect ultraviolet (UV) rays, drastically reducing the heat island effect prevalent in urban settings.

TPO membranes are typically white or light-colored, which enhances their ability to reflect sunlight, thereby mitigating heat absorption. This reflective quality aids in maintaining cooler building interiors, diminishing reliance on air conditioning systems, and consequently lowering energy consumption and associated costs. For building owners and occupants aiming for an eco-friendly and financially-sound solution, TPO roofing represents a strategically sound choice.

Furthermore, TPO roofing systems contribute to enhancing a building’s overall energy efficiency ratings and can assist in meeting stringent building codes and standards. This performance advantage is particularly beneficial in climates where intense solar exposure is a concern, ultimately underscoring TPO roofing systems as an ideal component for constructing environmentally-conscious and energy-efficient structures.

Cost-Effective Durability

One of the key benefits of TPO roofing systems is their cost-effective durability, which makes them a preferred choice among building professionals. This longevity is attributed to TPO’s unique formulation, designed to withstand the rigors of both environmental and mechanical stresses.

As a thermoplastic polyolefin, TPO integrates the resilience of rubber with the durability of plastic, delivering a robust performance that safeguards buildings over time. Its ability to resist ultraviolet radiation, chemical exposure, and punctures enhances its life span, minimizing the frequency of maintenance and replacement, thus consequently offering significant cost savings.

Moreover, TPO roofing systems are valued for their financial viability without compromising quality. The initial investment is balanced by reduced maintenance costs and the extended lifespan of the material, contributing to an overall lower cost of ownership. This economic efficiency appeals to property owners and managers seeking to optimize operational expenditures while ensuring reliable protection for their assets.

The ease of installation further enhances the cost-effectiveness, reducing labor expenses and installation time. As a community invested in sustainable and economically sound practices, embracing TPO roofing systems contributes to a shared commitment to intelligent building solutions.

Environmental Impact Reduction

Renowned for its environmental benefits, TPO roofing systems play a pivotal role in reducing ecological footprints. These systems, distinguished by their white reflective surfaces, effectively mitigate the urban heat island effect by deflecting solar radiation away from buildings. Consequently, they drastically decrease the necessity for air conditioning, leading to a reduction in overall energy consumption.

Their thermoplastic nature allows them to be crafted without the use of harmful chlorine, a testament to their commitment to environmental safeguarding. Additionally, TPO roofs can be fully recycled at the end of their lifespan, thereby minimizing waste and contributing to a circular economy.

Manufactured to endure harsh weather and environmental conditions, TPO roofing materials demand fewer resources for maintenance and repairs compared to other roofing options. This durability extends their life, decreasing the frequency of replacement and subsequently reducing the consumption of materials and energy associated with roof production and installation.

Beyond their environmental function, these roofing systems also enhance the building’s green credentials, aligning with the growing corporate and community drive towards sustainability. Within a community aware of its impact on the planet, TPO roofing systems present a harmonious solution, embodying sustainability while fostering collective responsibility for ecological preservation.

TPO Installation Process Basics

In the fundamental stages of installing TPO roofing systems, attention must be paid to the meticulous surface preparation, guaranteeing the substrate is clean and ready for adhesion, followed by the careful selection of membrane attachment methods which can vary based on structural and environmental considerations. Additionally, seamless continuity is achieved through precise seam sealing techniques that are indispensable for roofing longevity and performance. The following table outlines essential elements involved in each phase of the TPO installation process:

| Installation Phase | Key Steps | Considerations |

|---|---|---|

| Surface Preparation | Cleaning and smoothing of substrates | Ensures ideal adhesion |

| Membrane Attachment Methods | Selection of mechanical fasteners, adhesives, or ballast systems | Dictated by building design |

| Seam Sealing Techniques | Application of hot air welding or specialized adhesives for membrane joints | Crucial for waterproof integrity |

Surface Preparation Steps

Effective surface preparation is a pivotal first step in the successful installation of TPO roofing systems. This fundamental phase guarantees the substrate is adequately primed to receive the TPO membrane, thereby promoting optimal adhesion and longevity of the roofing system.

The process begins with a comprehensive evaluation of the existing roof surface, identifying areas requiring repair or reinforcement. Debris, dust, and contaminants must be meticulously removed through sweeping or power washing, which provides a clean and uniform surface.

Condition assessment is essential, and any substrates compromised by water damage or structural defects must be addressed. Proper drainage should be confirmed to prevent water pooling, which could compromise the membrane’s integrity. In addition, moisture content in the substrate should be carefully measured to avert potential issues with adhesion.

Where necessary, leveling compounds may be applied to ensure a flat and even surface, enhancing membrane performance and durability. Special attention should be given to edges, protrusions, and junctures, ensuring they are ready for detail work that guarantees a weather-tight seal. By adhering to these precise preparatory steps, the installer lays a foundation for a durable and efficient TPO roofing system.

Membrane Attachment Methods

The membrane attachment methods are critical to the performance and longevity of TPO roofing systems, offering various options to accommodate different project requirements. Mechanically attached systems, a common choice, involve fastening the membrane directly to the roof deck with screws and plates, providing durability and resistance to uplift in regions with high wind exposure. This method allows for speed and cost-effectiveness while ensuring sufficient security for the TPO membrane.

In contrast, fully adhered systems utilize a bonding adhesive to secure the membrane to the substrate, delivering an aesthetically pleasing finish with enhanced waterproofing capabilities. This approach is well-suited for projects where increased insulation or irregular roof surfaces are present, offering enhanced flexibility in roof design.

Another prevalent technique is the ballasted system, where the TPO membrane is loosely laid over the substrate and held in place using heavy materials like gravel or pavers. This method is ideal for roofs with large areas where additional weight is not a concern and is valued for its lower installation costs.

Each method presents distinct advantages, allowing stakeholders to select the most suitable approach that meets the specific functional and environmental needs of their TPO roofing project.

Seam Sealing Techniques

Seam sealing techniques are essential to the integrity and longevity of TPO roofing systems. Ensuring watertight seams enhances the overall performance, offering superior protection against environmental challenges.

TPO (Thermoplastic Olefin) membranes rely on precision and expertise to achieve a seamless finish, mainly utilizing heat welding methods that promote reliability and durability. As the membranes are heat welded together, a chemical reaction fuses the sheets, creating a coherent, monolithic barrier against moisture infiltration.

The process requires a skilled technician who understands the nuances of heat settings and speed, balancing these two variables to accommodate varying environmental conditions and membrane thicknesses. This mastery is critical in mitigating potential weaknesses, thereby delivering effective and enduring sealant solutions.

Safety precautions are integrated meticulously, ensuring both excellent outcomes and workforce security during installation. Specialized equipment, often automated, assists technicians in maintaining consistency across large expanses, while quality control protocols are enacted throughout to affirm seamless continuity.

These practices assure clients belonging to a community of property owners who value roofing solutions engineered for robustness and efficiency. The outcome of proficient seam sealing reverberates through exceptional weather resistance, extending the lifespan of TPO systems considerably.

Connect With Us

Ready to elevate your commercial building with a durable and energy-efficient TPO roofing system? Don’t wait any longer—connect with ARCM Information to learn about the benefits of TPO roofing.

Whether you need a new installation or a repair, we’re here to help. Call us now at (303) 306-8384 to schedule your consultation and discover the difference a high-quality TPO roof can make for your business.

Your satisfaction is our priority, and we can’t wait to partner with you for your roofing needs. Reach out now and let’s get started!

Roofing FAQ

How Does TPO Roofing Compare to Other Single-Ply Roofing Options in Cost?

In comparing single-ply roofing options, cost varies considerably. While TPO tends to be more cost-effective than EPDM or PVC, the decision should also consider long-term durability, energy efficiency, and regional climate, ensuring ideal value and community alignment.

What Is the Expected Lifespan of a TPO Roofing System?

The expected lifespan of thermoplastic polyolefin roofing systems typically ranges from 15 to 20 years, depending on factors like installation quality and environmental conditions. Proper maintenance can extend its longevity, proving its value within the roofing community.

Can TPO Roofing Handle Extreme Weather Conditions Effectively?

The ability of roofing systems to withstand extreme weather is essential for resilience and longevity. While designed for durability, performance can vary based on factors like installation quality and specific weather conditions. Professional consultation guarantees optimal results and community assurance.

What Maintenance Is Required for TPO Roofing Systems?

Regular inspection and cleaning are essential to maintain satisfactory performance. Check for punctures, seams, and flashing integrity. Address debris accumulation and guarantee drainage systems are clear. These practices certify longevity and reliability of your roofing system.

Are TPO Roofing Systems Available in Different Colors or Designs?

Yes, these systems are available in various colors and designs, offering customization to suit diverse architectural styles. This versatility guarantees/secures they blend harmoniously with existing structures, fostering sustainability and a sense of unity in built environments.